Years of Excellence

Trusted ExpertiseElectroplating Experts for Hybrid Connectors

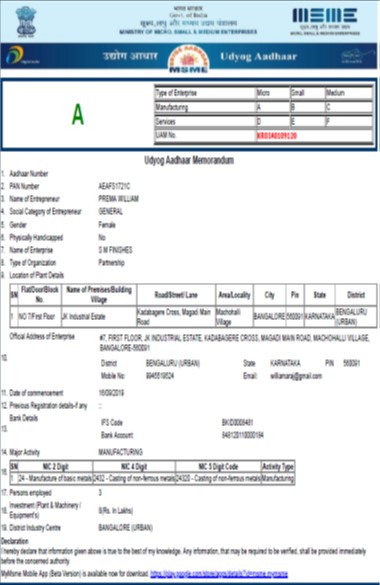

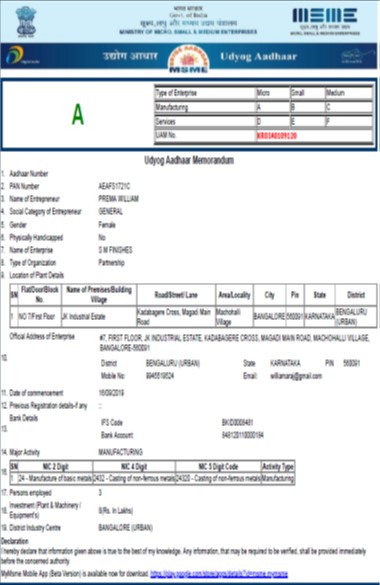

Since 2019, SM Finishes has been the trusted partner for industries requiring superior electroplating solutions for hybrid connectors. Our journey began with a simple mission: to deliver electroplating excellence that transforms ordinary metal components into extraordinary, durable, and high-performance hybrid connectors.

Today, we stand as Karnataka's premier electroplating facility for hybrid connectors, serving diverse sectors including automotive, aerospace, electronics, defense, and railway. Our commitment to innovation, quality, and customer satisfaction has made us the preferred choice for companies that demand precision plating for hybrid connectors.

20+

Customers

50+

Projects

About the Founder

William Anthony Raj

The driving force behind S M FINISHES, he brings strategic vision and hands‑on expertise to every engagement.

SMF engages in electroplating engineering and its know‑hows to support the electroplating technocraft and its environment.

- An Engineering graduate with a Master's in Business Management, bringing 27 years of technical and commercial expertise in connector manufacturing industries. His deep understanding of contemporary connector applications inspired the creation of SMF’s plating service unit.

- Gained and shared electroplating practices and specializations (Reel‑to‑Reel & Barrel processes) through professional visits to Belgium, Germany, France, China & Singapore.

Welcome to Solutions for Metal Finishes, a trusted innovator in electroplating with a commitment to global excellence.

Our Mission

Our mission is to deliver superior electroplating solutions by applying high-quality coatings to diverse materials, ensuring precision, durability, and performance that meet the evolving needs of manufacturing and industrial clients worldwide

Our Vision

Our vision is to be the leading surface-finishing partner in Karnataka and South India, delivering comprehensive, high-quality coatings backed by world-class expertise and exceptional service.

Metal Finishes, Process and Specifications

Pure Gold – 24K

High purity finish ideal for premium conductivity and corrosion resistance.

Pure Gold – 2N / 3N

Decorative and functional finishes with controlled hardness options.

Alloy Gold – Co

Engineered alloy layer delivering wear resistance for demanding connectors.

Silver

High conductivity plating for power, EV, and aerospace applications.

Copper

Uniform copper build-up for shielding, bonding, and leveling operations.

Nickel

Versatile barrier layer supporting R2R, barrel, and rack processing.

Tin – Bright & Matte

RoHS-compliant tin finishes for solderability and corrosion protection.

Electroless Nickel – HP & MP

Autocatalytic deposits providing uniform coverage on complex parts.

Passivation

Stainless steel treatments for enhanced corrosion protection.

Customer Audits & Approvals

Schneider Electric India Pvt Ltd

- Metallic Coating Technical Audits V1

- EHS Risk Assessment V2016

KOSTAL India Pvt Ltd

CQI-11, 3rd Edition audit

JINRONG Precision Machinery Pvt Ltd

SQA Capability V2 audit

ESCO Coupling & Transmissions Pvt Ltd, Belgium

Development, PPAP Audit & Release

SUZUKI Motor Corporation, Japan

PPAP Audit & Release

Maruti Suzuki India Limited (MSIL)

CQI-11, 3rd Edition audit

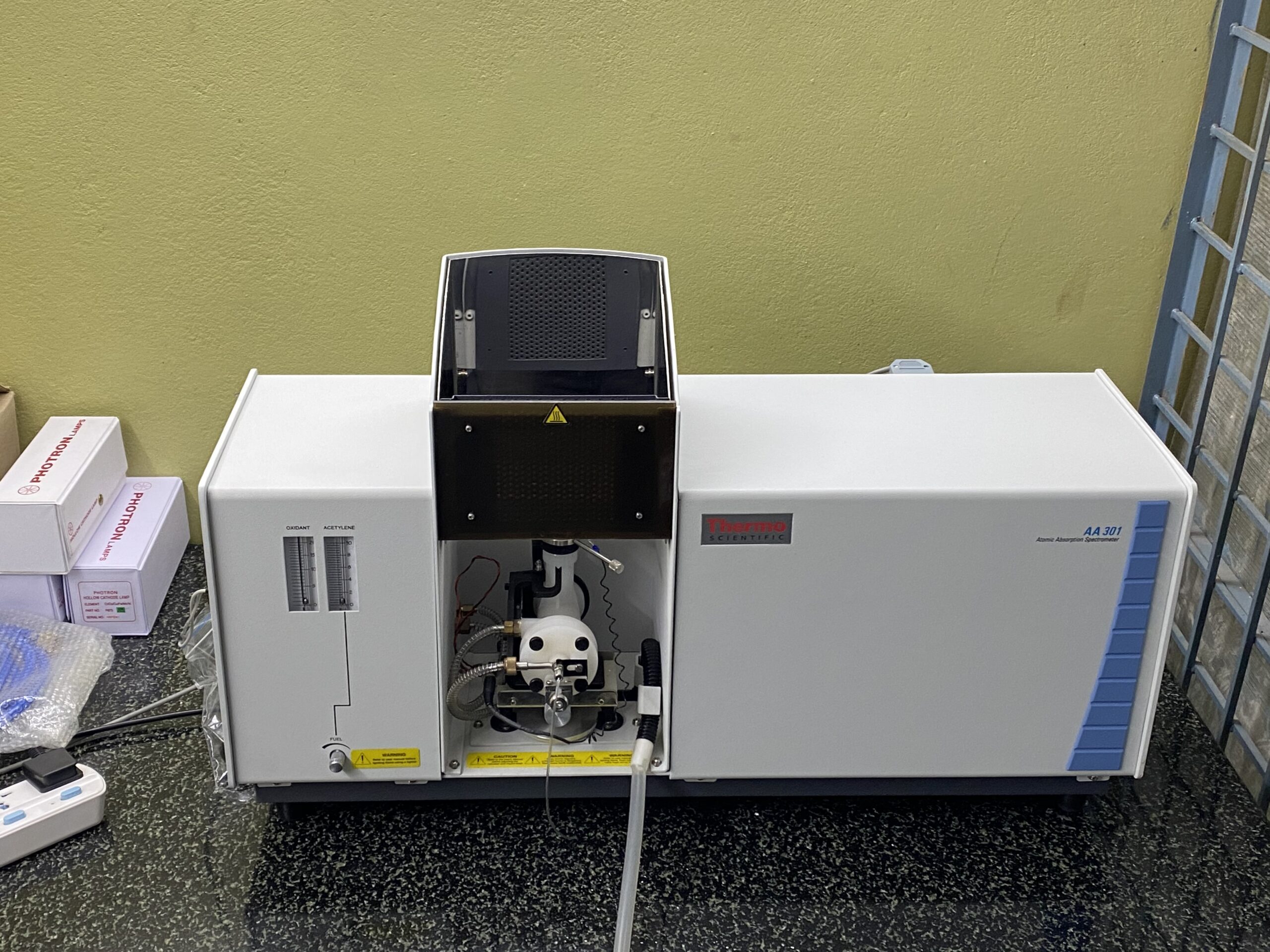

State-of-the-Art Infrastructure for Electroplating Solutions

Our Facilities

Time Breakthrough

2019

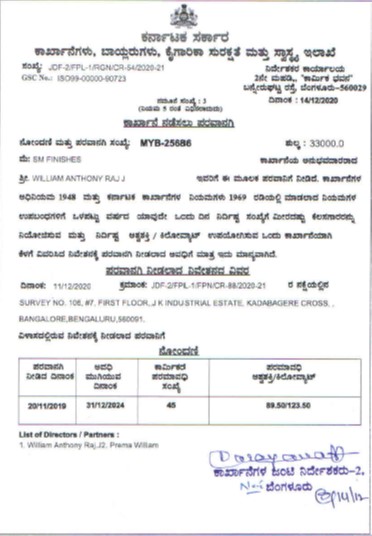

In October, SMF was formally established and registered, laying the foundation for our growth.

- Firm Formation

- Registration Completed

2020

From launch to first deliveries: August marked our official inauguration; by November we shipped our first defence production lot.

- August — SMF official Launch & Inaugural

- November — First Production lot Supplies for Defence

2021

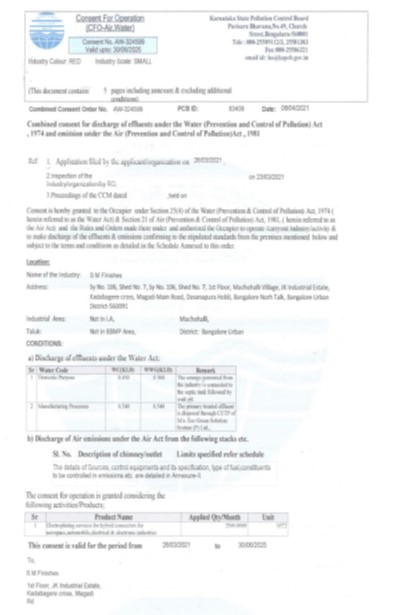

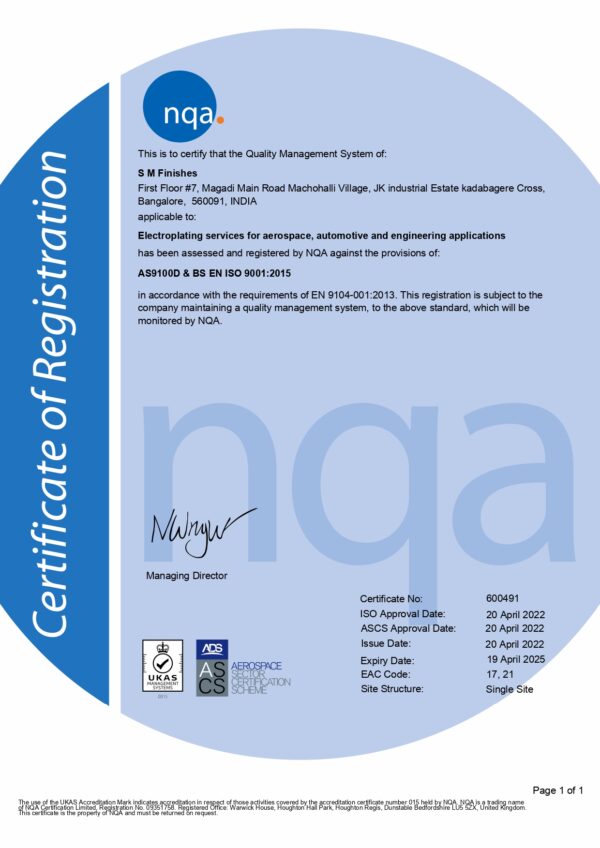

A year of quality milestones: PPAP approval for automotive programs in February and ISO 9001:2015 certification in July.

- February — PPAP for Automotive Industries

- July — Certification ISO 9001:2015

2022

In March, we achieved AS9100:2015 aerospace quality certification, strengthening our compliance for critical sectors.

- AS 9100:2015 Certified

2023

In August, we commissioned a high‑throughput reel‑to‑reel plating line to scale precision production.

- Reel-to-Reel plating line Installed

2024

In November, we earned ZED Bronze certification, recognizing robust MSME quality and sustainability practices.

- ZED Bronze Certified

- Registered as Pvt Ltd

2025

Expanding our capabilities with new plating technologies to serve our customers better.

- Silver plating rack process line added

2026

Continuing our growth with advanced tin plating capabilities for hybrid connectors.

- Tin process line added

Our Membership Forums

Our Certifications